At long last with the design decisions pretty well done

but still open to change as the bowls take shape the turning can begin. I decided to start with the medium size maple

bowl because if something goes badly wrong making another maple blank is pretty

easy. The process starts with finding

the center of the top of the blank. A

marking gauge is set to half the distance of the blank with lines drawn

parallel from all four sides. If the

gauge is set perfect then only two lines show up so the intersection gets

dimpled using a sharp punch and a mallet (red arrow). If it’s a little off there will be a gap with

a tiny box in the center and the center of that will be used. Once the center is marked a Fostner bit in

the drill press is used to drill a flat bottom hole for mounting on the lathe.

Mounting the blank in the lathe is next. That’s done by setting the just drilled hole

on the jaws of the 4-jaw chuck then expanding them holding the blank in place

in the top photo. If everything were

absolutely square and parallel with all the glued-up layers then I could mark

the center of the bottom face and use that to locate the live center. Because this blank consists of layers, I

want the joints to be 90 degrees to the center axis of the lathe so the glue

joints between the layers are parallel to the top and bottom of the finished

bowl. If the bowl’s mounting points are

out of alignment then the joint lines will run at an angle and visually that

would cause me a problem. To get it

right the tool rest is set so it’s close to one of the blanks corners, the red

circle shows that reference point in the top photo while the bottom photo is a

close view. The bowl blank is turned and

adjusted until all the corners are the same distance away centering that end

about the lathe’s axis.

With the bowl blank squarely in place the tail stock is

brought up to the blank and the pointed live center pressed into the

blank. Out of curiosity I had marked the

center of the face and it was really close to where the live center point

actually hit.

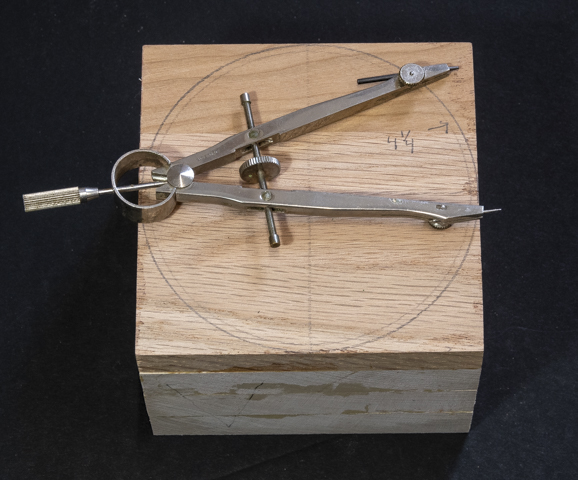

Using the center point I could layout an inscribed circle

within the square block and also mark where the edge of the bowl would end

up. As this is a medium size bowl its

finished diameter is 4 ¼” and the inscribed circle is 4 ½” so there is 1/8”

between the bandsaw line and the finished bowl diameter.

Next using the bandsaw I can cut a rough circle which

will make the first step of turning of the bowl to a constant diameter cylinder

a lot easier.

Mounting the bandsawn piece back in the lathe is

next. Because I am working off of two

known center points with the lathe the piece can be taken out of the lathe then

put back in with near perfect alignment time and time again. The first turning step is to get rid of all

the bandsawn roughness ending up with a smooth cylinder the same dimension from

one end to another. As the photo shows there

is still a little bit more turning needed to get the cylinder down to its final

diameter. The curly shavings and smooth

surface of the cylinder indicate the lathe tool is sharp and doing its job.

Here is a straight on view of the blank. The red arrows point to the joints between

the three pieces and the pencil lines indicate the top and bottom of the

finished bowl. Also, on the left you can

see the spigot on the 4-jaw chuck that goes into the drilled hole in the blank

that centers and holds the blank in place.

Once the blank is turned to a cylinder that is the bowl’s

top rim diameter layout can be done using the dimensions off the top

drawing. With three sizes of bowls there

is a drawing for each of the sizes. The

drawing shows where references lines are set measured from the top of the

bowl. At these points a notch is cut

just short of where the bowls face will end up.

For instance, the notch identified by the red arrow in the bottom photo

is 1 9/16” down from the top and if cut right to the bowls surface would be

11/16” deep. However, it’s actually cut

1/32” less at 21/32” so there is some room to smooth out the shape. One other bit of work has been done which is

to turn the sacrificial layer on the right side down to the diameter of the of

the bowl’s base. Both it and the top

diameter of the bowl will be used as reference points when doing the final to

size turning.

Using the slots as depth gauges the excess material is

cut away leaving a rough profile of the bowl.

This is refined using the template I made earlier to check the

profile. This is important since I want

matching sets of bowls. As I get close

to the final size the lathe is stopped frequently to check my progress. Unfortunately, there is no undo button on the

lathe and if too much gets cut away it’s a problem so it pays to be very

careful when doing the last little bit of work.

The maple bowls have three black decorative lines near

the top and one close to the bottom as shown in the rendering on the left. The right photo shows their approximate

layout with the red arrows showing the eventual top and bottom of the

bowl. However, before making the lines I

needed to turn the cherry bowl to verify their location. That’s because the feature bands in the

cherry blank are integral and as they are a part of the glue-up so can’t be

changed. The other feature bands are

applied after the exterior profile is turned and so their placement is a little

flexible.

The process to turn the cherry bowl is the same as the

maple one so I won’t go through that again.

Once turned the centerline of the banding in the cherry bowl is checked

against what had been laid out on the maple bowl. Good news is that they matched so I went

ahead and made the black lines.

Unfortunately, I was so concentrated on adding the lines in the correct

place that I forgot to document the process.

That’s not a problem as I will cover it when the small maple bowl is

made since the process is the same. The

photo below shows the profiles of the cherry bowl on the left and the maple

bowl on the right. Note that both of

them have excess material at the top and bottom that will be removed later.

Next Up – Turning Reference Stick & Making Black Feature Lines