This project is going to start with more than the usual amount of background information regarding the design process including 3D drawings, photo renderings and some prototypes so bear with me as I explain how this project unfolded.

Not too long ago while my wife and I were having a video

call with our son I asked him if he had any ideas for a belated Christmas

present. I had asked him if he was

interested in me making him something like our end grain cutting board. He said not really as they already a cutting

board that gets limited use, works just fine and might end up as a display

piece. We kicked around some things then

he mentioned that as a board gamer he had looked at several different kinds of

containers to hold the game’s pieces during play and hadn’t gotten anything

yet. This piqued my interest in that it

was something he wanted, would be used and I could make. We discussed various shapes including

triangular, square, hexagon and round with or without a base. I liked the idea of doing something round

that could be turned on a lathe which would allow design freedom along with the

ability to use a single form. It would

also allow for the ability to have different types of feature accents and he

agreed with the idea. After those intial discussions I sent him several different shapes and forms of feature

accents.

Additional discussion regarding functional design

requirements included the holders having gently curved interior sides so pieces are

easily removed, wider that tall for same reason, stable, graduated sizes for

holding different sized or different quantity of items and stackable to reduce

storage requirements. Here was an early

quick 3D drawing used after the general shape had been decided on and the

initial size had been increased but not finalized.

As it turned out even our revised size bowl that’s 3 ½”

in diameter holding ½ a cup was too small for anything but the smallest size. Upsizing the other containers we settled on three bowls at 3½”, 4 ¼” and 5”

in diameter with proportional heights.

This will also give the ability for them to stack for storage.

By now we had decided that there would be three bowls in

a set and four sets for a total of 12 bowls.

At this point I took the mid-sized bowl and did some 3D drawings showing

a couple of ways they could be embellished, just to get things going.

Next is to discuss what the bowls would be made out of

as we wanted each of the four sets to be made from a different wood. I came up with five different possibilities:

cherry, oak, maple, walnut (not shown) and leopardwood.

In the end the leopardwood got dropped because that while the figure of

the wood is striking it probably would be too much given that we had planned on

adding some sort of feature accents to the bowls. Also, it would have required more pieces glued together to get the size turning blocks needed than I wanted to see.

So far all we have had to work with is flat 2D drawings

and some 3D renderings. To get a better

idea of what the actual piece would look and feel like I decided to make a

middle size bowl out of cedar. This is

the same material as used to make the prototype of the just completed

Wastebasket. Since the raw piece to be

used is rough sawn and has a bit of a twist the blank gets cut into smaller

pieces (top photo) then the low corners get shimmed until the blank sets flat

(bottom left). From there it gets run

through the thickness sander until the surface is flat and smooth. The bottom right photo shows this in progress

where the high corners have been knocked off.

The top photo shows what a finished piece looks like and

the bottom photo shows the layers cut to size and ready to be glued together.

Gluing the pieces into a block is next. Here the large red clamps hold the stacked

pieces in alignment while the grey clamps apply the downward clamping pressure

to the glue joints. I might have used a

little bit too much glue on the joints.

After a few minutes to give the glue a chance to “grab” the large red

clamps are removed and the excess glue cleaned off.

Next is to make a template for the middle-sized bowl

which is the bottom one in the top left drawing. At the top right is after I cut it out using

a jig saw. The bottom left is the

oscillating drum sander ready to begin fine tuning the template. This drum will take care of most of the

cleanup but as I need to get into tighter radiuses the drum gets swapped out

with smaller and smaller ones. The fine

cleanup is done with fine files and sandpaper ending up with the template at

the right bottom.

After the glue cures overnight, the center is located and an oversized circle is drawn with a compass then cut out using the bandsaw. Mounting the block in the lathe is next. First the drive center gets a good whack with

a mallet leaving tooth marks in the block which will provide a good grip for

turning.

Here the piece has been mounted in the lathe with the

drive center on the left and the live center which freely spins around on the

right. Turning the block round to an

even diameter cylinder is next. A nice

sharp turning tool generates the wispy shavings shown. If you are not getting those then the tool is

not sharp enough.

To drill a centered mounting hole in the blank I will use

my 4-jaw chuck to hold the piece with the center line of the blank aligned with

the lathe’s axis. For various sized

pieces I have four different sized jaw sets.

Here three are shown and I will use the largest of them.

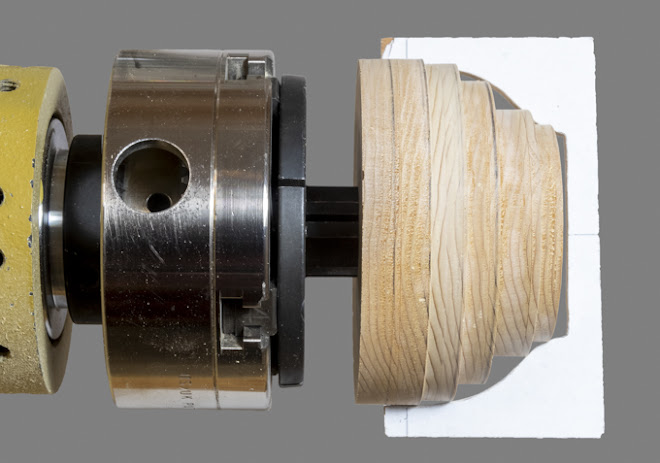

In the top photo the blank has been secured in the 4-jaw

chuck using the live center to align the center of that face with the lathe’s

axis. The bottom photo shows the live

center replaced with a Jacobs chuck and a Fostner bit so a mounting hole can be

drilled. In this method of drilling the blank spins and the bit does not move.

With the mounting hole drilled the blank is removed, the

chuck’s jaws get swapped out for the smallest set, the blank reversed with the

newly drilled hole mounted over the jaws.

They are then expanded to hold the blank in place and the exterior can

be turned to shape. This photo shows the

blank rough turned.

Turning continues until the blank fits in the

template. Part way through I found that

a half template worked a lot better than a full one. After going through making the prototype I

also found that swapping the chuck’s jaws is not the fastest method to set up

the mounting since swapping out the jaws takes some time. With 12 of these to turn I want to streamline

the process where possible. When I get

to the actual bowls I will go through the revised mounting process.

Next Up – Finish Turning Prototype & Different Feature Accents

No comments:

Post a Comment