When I built the stained-glass panels that will go in the

doors back in the late 90’s the glass was not grouted or cemented in the zinc

came. That’s because since they were

mounted in sliding glass doors any moisture condensation that accumulated

between them and the door glass would have a way to escape. That worked well in that situation but now

since they will be mounted in an operating cabinet door, I need cement or grout

the well over 500 pieces of glass per window solidly in place in the zinc came

to help provide rigidity for the door assembly.

The process starts out by laying one of the panels on a

piece of carboard to protect my workbench as cementing or grouting can get a

bit messy.

In their original installation in the sliding glass doors

there were 6 copper tabs on each panel that were used to mount the panel in the

door. The left photo below has a pencil

pointing to one of them and the right is a closer view of the same one.

Because they will not be needed when they get mounted in

the doors they need to removed.

Since they were soldered on a little heat with the soldering iron

removes them. In the left photo I am

heating the tab and in the right one it has been removed. I did do a little cleanup on the joint after

the photo was taken to make the result look a little better.

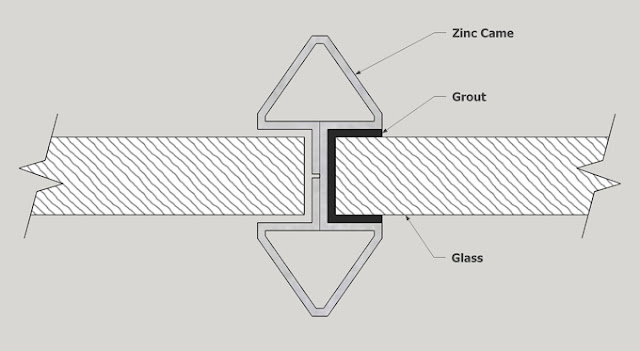

Next is to do the grouting which will fill the gap

between the zinc came and the glass. The

drawing below shows a cross section through a typical piece of zinc came plus

the glass. The left side is before

grouting while the right shows the final grouting. This will anchor the glass in place and make

the whole window more rigid and stronger.

It has been a long time since I did any window grouting

and the materials have changed since then. Since nothing was available locally, I was

left with ordering the material online.

Previously the grout was like cake batter while the current grout is

very thick, more like a putty. Because

of the material change the grouting process changed too. This meant there was a bit of learning curve

(2 days) before I got any proficiency in putting it on. With that in mind here is the process I am

currently using to install the grout.

Step 1: Using a 2” wide putty knife a small quantity of

the grout is applied to the glass/came joint and pressed into it until no more

can be packed in. For me holding the

putty knife near the tip with both hands gives good control and allows me to

easily apply sufficient pressure to really pack the material in. One thing to remember is that the idea is to

fill the gap between the glass and the came so the direction of the applied

force is parallel to the surface of the glass.

Minimal downward force against the glass is used to prevent

scratching or worse cracking a piece of glass.

This worked well where the lengths of the came were

longer than the putty knife. However,

there are a lot of narrow or just small pieces in the window. Moving to a smaller 1” wide putty knife

helped but still did not allow me to get in the smaller spaces. My solution was to take a couple scrap pieces

of wood and rip them down to half and quarter inch wide strips then bevel the

end.

Here is what it looks like when I get that done in an

area. For this window a square foot

takes just under an hour. Areas with

mostly large pieces take less time.

Step 2: Trimming the grout is next. That cleans up the joint and gets rid of the

excess grout. There are a couple of

specialized tools that can be used or in my case I took a scrap of oak and

turned it to the profile I wanted in the lathe creating my own “pick”.

The pick is run around each piece of glass and. In use the pick is held 90 degrees to the

glass tight to the came then run around each piece of glass which trims off

most of the excess grout leaving a fairly nice edge. At the same time each glass to came joint is

checked to make sure it has grout and was not missed. Any missed spots are fixed.

Step 3: Cleanup is next.

There are a couple of materials that can be used to clean the excess

grout from the came and glass. One is

whiting or calcium carbonate and the other is very fine sawdust. The sawdust is not what you would get from a

tablesaw or similar tool but the very fine, almost flour-like dust that is the

result of sanding. As it just so happens

my thickness sander makes this type of sawdust in copious quantities that is

sucked up by the dust collector. When

starting the grouting the dust collector bag was about half full which gave me

over a 5-gallon bucket of just what I needed at no cost.

Step 3: Cleanup is next.

There are a couple of materials that can be used to clean the excess

grout from the came and glass. One is

whiting or calcium carbonate and the other is very fine sawdust. The sawdust is not what you would get from a

tablesaw or similar tool but the very fine, almost flour-like dust that is the

result of sanding. As it just so happens

my thickness sander makes this type of sawdust in copious quantities that is

sucked up by the dust collector. When

starting the grouting the dust collector bag was about half full which gave me

over a 5-gallon bucket of just what I needed at no cost.

Here is what the window looks like after liberally

sprinkling the sawdust over the just grouted area.

A moderately stiff natural bristle brush is used with

modest pressure. Too much and you risk

the chance of breaking a piece of the glass.

The sawdust and scrubbing cleans off the excess grout turning the

sawdust a darker color. When it looks

like the excess grout is mostly combined with the sawdust a shop vacuum is used

to remove most of the sawdust/grout mix.

Some will still be packed into corners.

Another pass with the brush is done to remove as much of

the sawdust/grout mix as possible then vacuumed away followed by gently

sweeping the surface with a soft brush and blowing it off with compressed

air. Since I generate more sawdust than

I can use I don’t bother trying to reuse it.

Step 4: Tool or detail the came/glass joint. With the sawdust and excess grout removed I

check again for any missed areas or grout that needs to be fixed. Once any repairs are done it’s time to finish

the came to glass joint. At this point

the grout will probably have a little bit of a bevel between the glass and the

zinc came. Below on the left is what

that looks like and on the right is what is wanted.

Step 5: Last step is to take a soft cloth like an old

cotton tee shirt and clean any of the odd remaining spots of grout off. Below is what a finished section looks like

which is pretty much the same as before.

Start to finish it takes about an hour and 20 minutes per square foot of

window. There is a bit over 12 square

feet per side of window so that works out to roughly 16 hours per side. Yes, you have to do both sides.

As mentioned earlier I made a rough guess

on how much I needed and ordered the largest size available. As it worked out, I used about ¾ of the

container on one window so will need to order more. That’s OK as I am really tired of grouting so

will wait on doing the second window and move on to making all the pegs.

Next up – Pegs

No comments:

Post a Comment