At this point it’s time to start the glue up. After some thought I was pretty sure that if

I tried to glue up all four corner joints at once it would be a problem. Because there are so many different surfaces

in the box joints, I was afraid the glue would start to set up before I could

get it assembled and clamped. To reduce

that possibility only two corners will be done at a time. Somewhere in the forest of clamps below is

the wastebasket. This just goes to show

the old saying of, “You can never have too many clamps.” is really true.

After gluing the other two corners together and letting

the clamped assembly cure overnight here is the end result. The photo on the right is a close view of the

glued corner in it you can see the slight bit the pins and tails extend. That’s because it’s easier to sand them flush

versus trying to bring the whole face down flush. For the real wastebasket I will reduce the

depth of cut just a little so I don’t have so much to remove to bring the

joints flush.

Bringing them flush is done using a random orbital sander

with a 60-grit sanding disk to carefully sand them just flush. The sanding disk then gets changed to a finer

120-grit disk and the whole surface is sanded smooth. The bottom photo is a closer view of the

finished surface.

Making and installing the supports for the bottom are

next and are made from leftover pieces of cedar. The top edge gets an angle cut to match the

slant of the of sides so the bottom lays flat on them. That’s easy since the table saw still has

that angle set on it. Next, they get cut

to about ¼” square. To mark their length

a sharp marking gauge is used. That’s

shown in the photos below. Once cut they

get glued in place and nailed using a 22-gauge pin nailer.

The bottom is cut from a piece of ¼” oak veneered plywood

with the edges beveled to fit the tapered sides. This is what that looks like from the bottom

and while the plywood looks pretty bad, which it is, that’s because this

leftover only had one good veneered face and that’s on the inside.

The bottom is installed next by applying a thin bead of

glue on the supports. Clamping it in

place while the glue cures is shown in the photo below. No mechanical fasteners here. Actually, the only mechanical fastening in

the whole piece are the pin nails used to hold the supports in place while

their glue dries.

Once the bottom is installed final sanding is done which

includes softening all of the sharp corners with a sanding block and hand

sanding. The left photo shows the

wastebasket done and ready to finish. I

had not planned on putting on a finish this piece because I anticipated more

problems in getting the jig to work and thought the test pieces would get used

up solving problems in the build. That

was not the case so it’s going to get a finish which will be four coats of

Watco Danish Oil finish. Since the cedar

is a soft wood, I think that it will get dinged up over the years and this type

of finish is easily reparable. The oil

also results in a nice warm color as shown in the right photo.

At this point the testing is done and I can start on the actual wastebasket to be made out of cherry. This build will follow the same process as the test piece so going through the whole process would be redundant. My plans are to take occasional photos along the way at various milestones to let everyone know how it’s going.

Here in the top photo the cherry has been ripped to ½”

thickness with all three pieces glued and clamped together. The photo on the right shows a straight ruler

being used to check and make sure the glued-up boards are flat and not

bowed. If there were a bow light would

be visible under the ruler. The bottom

photo is after the panel has been squared up, trimmed to width and sanded with

220 grit.

All went well with cutting the individual tapered panels

to size. Using the jig to cut the box

joints also went well or at least I thought it did until the first test

assembly. For some reason two of the box

joints in two panels were not cut to the correct depth and are about 1/32” too

shallow. I have no idea why since they

were all cut with the same setup plus the ones on either side were fine. I suppose that’s better than being too deep

since the fix is to recut those to the proper depth. The problem is getting the pieces back

exactly where they were in the jig to begin with because if the alignment isn’t

perfect the joint is going to be cut too wide and there will be a gap. Ordinarily with non-tapered pieces this would

be easy, just butt the piece up against the reference board. However, with the taper when the first joint

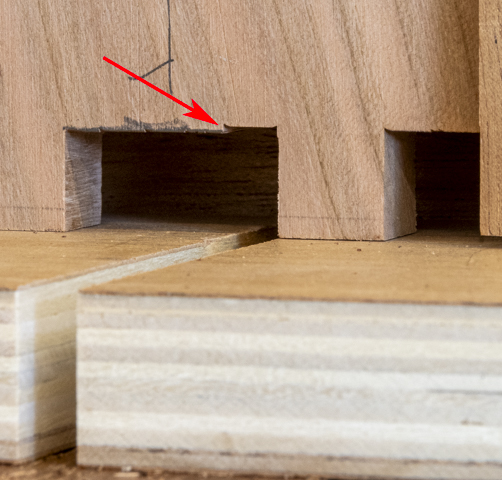

is cut a little bit of the reference point gets cut off. This photo shows the gap with the piece

correctly aligned.

To get the alignment rather than eyeball the location I

used the original spacer (red arrow, bottom photo) when the location was set for

the Vertical Indexer. With the spacer in

the slot cut by the dado blade the piece is set tight to it and clamped in

place.

With everything set the first pass of recutting the joint

is made. Here the red arrow points to

where the cut was made just a little bit deeper. After both of the joints were recut when the

wastebasket was reassembled for another test fit everything fit together just

right. I would note that the depth of

cut made by the blade was not changed for the recut.

Next Up – Filling a Flaw, Assembly & Finishing

No comments:

Post a Comment