Cutting the fixed and adjustable backer pieces are

next. They get made out of a piece of ¾”

oak plywood I have on hand. Before

cutting them the tablesaw blade needs to be changed from the rip blade on there

that’s used to work on the “L” bracket glue-up. Below the top left Glue Line Rip blade is

what I use for cutting along the grain of the wood. An edge view of it is the left blade in the inset photo. To keep the plywood

veneer from splintering during cutting the tooth profile and count is quite a

bit different from the rip blade. It’s

the Precision Crosscut lower left blade and its edge view is the inset’s right

blade. A compromise between the two is

the top right “Combination” blade whose edge view is the center blade. Most of the time the Combination blade is on

the saw unless there is a lot of ripping to be done. The Precision Crosscut gets used only on

veneered plywood or when crosscutting solid wood.

For the adjustable backer part, a piece of oak plywood

gets cut to rough width and final length then a stopped groove is cut.

The groove is 5/16” wide and a tad over ¼” deep. It’s cut using a ¼” diameter bit in the

router table by making two passes adjusting the fence between them. These photos show the first pass completed. The first cut does not meet the line closest to the

fence because it’s just a rough reference line.

The actual accurate cut location is set using a scrap piece and dial

calipers.

Cutting the tongue on the piece of oak that has already

been laminated so it fits in the stopped dado is next. This part is shown in the drawing below.

The router bit gets changed from the straight ¼” diameter

bit used to the bit shown below. This

bit uses different guide bearings shown on the left and right of the bit to

make various fixed width cuts from 1/8” to ½”.

Since I wanted a ¼” width cut all I had to do was pick the appropriate

bearing.

This photo shows after a single pass has been made on

both the top and the bottom. Additional

passes will be made on the bottom until the height of the cut equals the

distance the stopped dado is set back from the edge. Once that’s done the piece will be flipped

over and additional passes on the top will be cut until the tongue fits in the

stopped dado.

Here the tongue has been cut to its final size. The piece of masking tape on the part is

because the blank is about .002” thicker at one end. Because the tongue is cut referencing the

faces it has that tiny .002” taper from end to end. The fix is to add the strip of masking tape

on the thin end then raise the router bit .002” and make another pass across

the router bit. The result is a .002”

cut which tapers to nothing at the taped end making a perfect fit. This photo also shows where the last inch of

the tongue has been removed so it fits in the stopped dado.

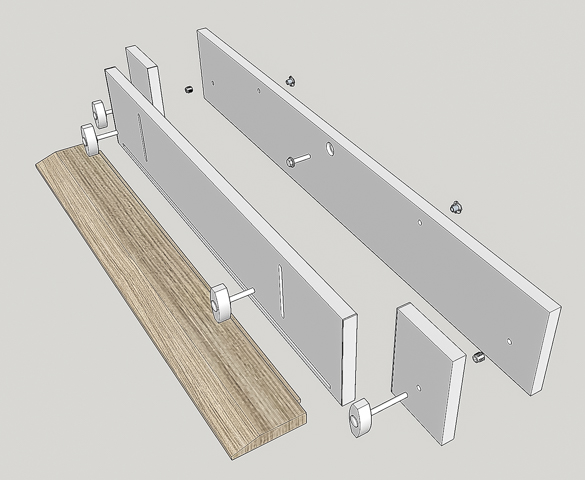

These two photos show different views of the stopped dado

in the plywood part and the tongue on the laminated oak part.

These photos show the table saw set to cut the beveled

edge on the laminated oak part. Here the

straddling assembly is attached to the table saw rip fence to add a little

height providing additional support when the laminated oak part gets

beveled. The yellow magnetic fence is set to

apply a little pressure to the oak piece to help keep it tight to the rip

fence.

Once the bevel is cut the two pieces are put together for

a test fit which looks like this.

Next is using the router to cut slots in the adjustable

backer. These will allow for the

vertical adjustment of the backer and laminate oak piece. In the drawing below the red arrows point to

those slots.

To make the slots a ¼” diameter router bit is used. Once the router fence distance from the edge

of the backer to slot is set left and right stops are clamped to the fence and

the first shallow cut is made. In the

photo you can see the right stop.

Because the slot is off center one end needs to be cut from the front

and the other end needs to be cut from the back so they match. Unfortunately, I cut the first pass on one of

the faces from the wrong side so the slot ends were reversed from what’s

needed. Fortunately, the fix is pretty

simple because the first cut was quite shallow.

A thin piece of oak gets cut to fit, glued in place then trimmed flush

with the face. The red arrow in the

photo points to the completed fix. If

you look just above the slot, you can see where I added, “cut this side out” to

prevent a repeat. Since the slot needs

to be 5/16” wide and the router bit is ¼” the fence gets moved away from the

bit so the slot can be cut wider. It is

important to move the fence away from the bit so the piece needs to pushed

toward the bit to make the cut. That way

the rotation of the bit does not pull the piece toward the bit. If the fence is pushed toward the bit, then

the rotation of the bit will pull the work toward the bit which can grab the

piece and rapidly pull it into the bit. If

that happens then the process can get away from your control and before you

have a chance to react things go bad in a hurry.

Here the adjustable backer’s slots are done and the “L”

fence is set into the stopped dado.

Next Up – #3 Plastic Laminate, Guide Blocks &

Starting Knobs

No comments:

Post a Comment