A waterproofing sealer and solid stain requiring two

coats is used for the finish. Since

there was not really a good way to hang all the pieces so all sides could be

painted at once only half of each piece gets done at a time. Giving them overnight to dry between coats

means it takes four days to finish all the parts. Here are all the almost finished pieces for

the swing. There is one end of each slat

still unpainted because that’s where their location number is written. While the slats are all the same except for

two the location of mounting holes vary slightly. With them numbered they can be put back on in

their original location.

The slats are added to the seat/back brace in the same

order as originally installed. Here they

are all in place ready for the numbered ends to be painted.

After mounting and screwing the long supports to the

seat/back braces the numbered ends get two coats of paint. While the paint dries the front and top rail

get screwed on. Last is to glue and

screw the arms on. Most of the screws

used are zinc coated since they are protected and will not get wet except in

extreme circumstances. The arm

attachment is different in that the heads of the screws will be exposed to the

elements. To reduce the chance of

corrosion or staining of the wood the screws used have multiple anti-corrosion layers . Fortunately for me I found some that are

almost the same color as the swing’s finish.

The red arrows show the installed screws and the inset shows what the

screw looks like.

The base starts with the top and bottom rails of the two

ends. Those are shown in blue in the

drawing below. They were roughed out

some time ago and have been waiting until I was ready to use them. In checking they are all good except for one

that has a tiny bit of a bow that I can work around.

Each part is made from two identical halves glued

together. This is the dimensioned

drawing of one of the top and bottom halves will be used to make them. There is one change from the original plan,

the corners are rounded rather than clipped at a 45-degree angle. I made the change for uniformity in design so

the curve of the arms and the seat/back braces is carried throughout the piece.

First is to do the layout of the dados which when the

halves are glued together will make up the mortises for the uprights. Three of the four sets can be cut with the

same setup since the blanks are all the same length. However, the fourth set (in front below) is

about an inch shorter than the rest so it will require a different setup. It would have been nice if they were longer

but there was not enough material in the 2x6 they came out of to make that

happen. However, when trimmed to finish

length they will all be the same.

The dados will be cut with a stacked dado. I choose not to rough them with a bandsaw

since they don’t have an open end to cut from like the seat/back braces

did. It would be fiddly work and take

more time than it’s worth to do that so I am just going to use the table

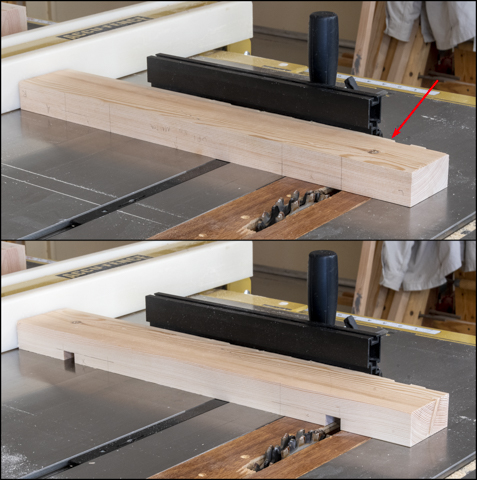

saw. In the top photo the rip fence

(white) sets the left right distance the dado’s get cut from the ends. The miter fence (black) keeps the piece

square with the blade and is used to push the piece across the blade making the

cut. Also, you can just see the backer

board next to the miter fence (red arrow) to prevent splitting when the dado

exits the cut. After the first cut the

piece is flipped end for end and the second dado is cut. The bottom photo has the first pass done.

After all the similar pieces have had their first pass

made the rip fence is moved closer to the blade and a second pass is made

expanding the dado. The top photo shows

one end with two passes. The bottom

photo shows the finished dados.

After all the dados are cut and the two halves stacked

together the mortises are clearly visible.

Next is to route a slot for a spline that the center

panel floats on. The drawings below show

the panel and splines along with where the slot gets routed. Both the top and bottom rails get routed with

the bottom rail shown.

Here is a closeup of the router table with the router bit

and fence set for the cut. Note that the

right side of the fence is really close to the bit. That’s to provide support to the wood fibers

on the exit side of the cut which reduces the splintering and chipping of the

edge.

Here the top photo shows both halves of the base with the

groove for the spline cut clamped together ready to be glued up. In the bottom photo the pieces are lying flat

with the surfaces to be glued up.

Gluing the pieces together is next and this photo shows

the fit up in the bench vice. To make

sure the two halves align perfectly side to side there are two blocks sized to

just fit in the dados cut and inserted in the assembly. In addition, to make sure the two halves

don’t slide around while gluing and clamping there are three screws run in from

the face for alignment. They will also

provide some clamping pressure. From

here everything is taken apart, glue applied and things reassembled in the bench

vice. Afterwards the blocks are knocked

out, more clamps are added and any glue squeeze out is wiped away. The next day the clamps and screws are

removed giving me mostly completed top and bottom rails for the glider’s end

panels.

Next Up – Finishing End Rails, End Stiles & Base Stretchers

No comments:

Post a Comment