The oak bowls are the last set to make. When I turned the small blank round and got

it down to the correct sized cylinder I noticed two substantial cracks. One was near the bottom that might get cut

away when the bowl got turned to shape.

However, the other one ended up right near the top edge and looked deep

enough that it would go all the way through to the bowl’s inside. I was worried that the crack being that close

to the top and going all the way through would make the top edge really

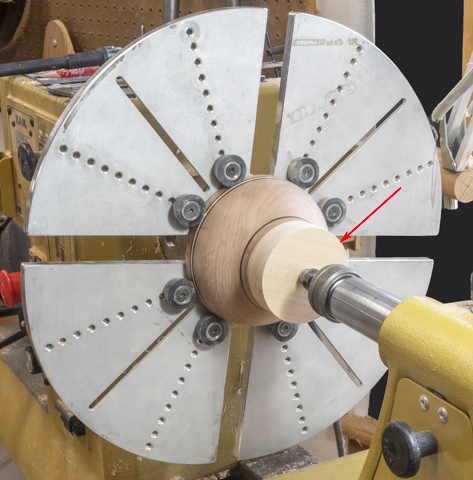

fragile. In the photo the top red arrow

points to where the rim will be and bottom arrow identifies the crack. After some thought this blank gets rejected and I have to

start over by making another one.

Because I was concerned that the resin used to set the

turquoise in place might stain the oak they got a coat of finish just like the

walnut ones before any work began. While

the decision had been made to add a turquoise band the details as to exact size

and location were still undecided. The

top photos below show two options for the medium bowl. The one on the left has a 3/8” wide turquoise

band centered on a line that matches the center line of the other bowls feature

ring. The right bowl has a 5/16” band

whose center is just slightly below the feature ring center line. After some discussion it was agreed that the

band on the left was a bit too wide and the space between its top and the top

of bowl was too small. In the end we

decided to use tentatively use the 5/16” band centered on the other bowls

feature ring which makes the oak band at the top real close to 5/16” also. The bottom photo shows the groove cut into

the bowl that gets filled with the turquoise.

As I was sneaking up on the width of the groove and its exact location

what ended up looking right was a 9/32” wide band 9/23” from the top of the

bowl. If the distance from the top of

the installed turquoise band to the top of the bowl doesn’t look quite right

then I do have a bit of wiggle room when the top edge is cut. Just have to wait and see how it looks when

done.

Adding the turquoise band is next. It consists of an ultraviolet cured resin

used as a carrier for the fine turquoise granules. Process is to mix the turquoise with the

resin at about four parts resin to 1 part turquoise then carefully put it in

the groove. Now to keep it from running

out only an inch or so at the top of the bowl (red arrow) is level enough for

the mix to stay put. With the mix in

place a UV light is used to set the resin so it’s solid enough to continue

which only takes about 30 seconds. Here

the last bit still has to be done but to see it clearly the bowl is rotated

toward the camera. It will get rotated

back so it faces up before filling.

Once the groove is filled the UV light is set close to

the bowl, turned on and the lathe set to run at its lowest speed for about 10

minutes to fully cure. Well, that’s what

I thought was going to happen based on testing I had done with a clear

sample. What actually happened was the

turquoise granules blocked the UV light so it couldn’t penetrate as fast and

far so it ended up taking a lot longer to harden the resin all the way

through. On the next bowl I will make

the band in more than one layer.

When the resin was finally cured it gets turned off flush

with the bowl and sanded up to a very fine 2,000 grit sandpaper. Next is to hollow out the bowl and round the

top following the same process as the others.

Turning the small bowl is next and we went through the

same process discussing the width and distance of it from the top as with the

other bowl. Decision was to decrease the

width of the turquoise band a little (1/32”) and center it on the same line as

the other small bowls feature bands.

Coincidently the width of the turquoise band and the distance between

the top of the band and the top of the bowl ended up being the same.

Last bowl to turn is the large oak one which has a couple

of cracks that are not as significant as was on the small bowl. The red arrows in the photo on the left show

the cut channel where the turquoise will get laid in and the ellipse shows the

aforementioned cracks. The right photo

is a closer view of the cracks. They are

fairly small and not too deep so the plan is rather than try and hide them with

filler I am going to celebrate the natural flaws in the wood and fill them with

turquoise. The bottom photo shows the

completed turquoise inlay.

At this point both the walnut and oak bowls are ready to

have their sacrificial bases cut off and the bottom finished. I waited to get both groups done before doing

this step because I have to switch out the jaws that are on the 4-jaw chuck to

the jumbo jaws to finish the bottom of the bowl and it takes some time to make

the change. OK really, I am too lazy to

keep swapping the chuck’s jaws back and forth.

Next Up – Final Turning and Lacquer Application