The three seat/back braces are made from 2x6 material

that starts by rough cutting them to length using the chop saw and a stop block

on the left so they are all the same size.

Care is taken during the layout to work around knots or any other

flaws. Since the finished pieces are 4¼” and

3” wide so there is some room for adjustment.

Running the blanks through the planer is next to remove

any cupping, clean up the rough construction lumber surface and bring them to

the desired 1 3/8” final thickness. All

told only about 1/16” is removed from each face. Here is the planer and vacuum setup. The planer makes a LOT of chips so using the

vacuum to collect them really helps keep the mess down.

From the planer the blanks are run through the table saw

to clean up and make parallel edges plus giving me my working width. Here’s the blanks along with the patterns

ready to go.

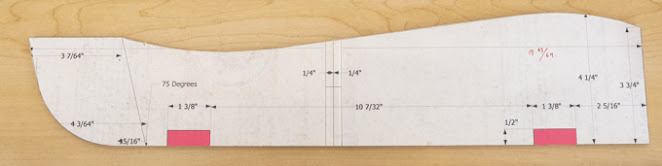

Next is to cut the half lap joints used to join the seat

and back braces together. That involves

cutting half way through the areas shown in red on the drawing below at a

75-degree angle to the straight base.

The miter fence is set to cut the 75-degree angle using

an adjustable triangle from my drafting days.

A stacked dado blade will be used to make the cut but the fence angle is

set with the regular saw blade in place since it gives me a bigger reference surface than the smaller dado blade.

This photo shows the cutting in progress. The 5/8” wide stacked dado is in place along

with a longer temporary fence and a stop block.

All of the parts got cut with no problems except

one. Here in the top photo, you can see

after the dado had been cut a hidden crack was exposed. Not at all what I wanted to see. In some cases where the part is hidden or

lightly stressed, I probably would not have been too concerned. However, this is a critical joint where the

seat and back come together so it’s a problem that had to be addressed. My solution is to fill the crack with 2-part

epoxy which is shown in the bottom photo.

There is one last little bit of work to do on the just

cut dados. They are not as smooth as I

would like for a structural joint like these that get glued together. You can see what I mean in the top board’s

dado cut joint. That can be easily

resolved so the surface looks like the bottom board. The fix is to use the dado blade to cut

sideways removing the roughness.

To do that the board is set so the high point of the

blade is in line with the face of the cut as shown below. The saw is turned on and the board is slid

toward the stop block and back. The

board is advanced forward a little and another pass is made. This process is repeated with the fence

moving forward a little at a time until the whole joint has been surfaced

smooth.

Once the epoxy in the cracked board had cured overnight

the same process cleaned up the epoxy leaving a nice smooth surface ready for

gluing.

With both halves of the half lap joint smoothed it’s time

for a test fit and as shown here everything matches up. The joints are tight on both sides and the

angle is dead on.

Before the seat/back braces get assembled two dados need

to be cut in the seat brace for the cross supports. They are shown here on the pattern

highlighted in red.

To get their exact width I need to cut two 2x4’s down to

the rough length and straighten them since they both had a bit of a bow. Last to get rid of a tiny cup plus clean up

the faces by running them through the planer. Actual process is to cut to rough length then using an 8’ level is used

as a reference edge create a straight edge.

The new edge is then set against the level and the first edge cut

straight. The important thing to

remember is to cut the crown of the bow first. With that done they can be run through the planer until the faces are flat followed by measuring their thickness and using that for the dado width. That ended up being about 1/32” over the 1

3/8” planned.

The dados are cut with a 5/8” wide stacked dado blade in

three passes, here is the setup with the first cut made near the right end of

the piece. Clamped to the table saw rip

fence is a stop block that controls the location of the cut. The seat brace with a backer board prevents the dado blade from chipping the backside of the brace when it exits the cut

are clamped to the saws miter fence. In

use a cut is made through each of the seat braces then the rip fence is

adjusted to take another cut widening the dado to just under 1¼”. The third and last cut is a bit of trial and

error so the dado just fits the cross support.

Shaping the curved sections of the braces are next. This is the top of the back brace after using

the band saw to cut about 1/16” wide of the line.

To bring the cut down to the line and finish the curve a

pattern cutting bit is used in the router table. The key to making this work is a router bit

that has a bearing at its top that follows the pattern cutting a finished

surface that perfectly matches the pattern.

After the pattern is attached to the rough-cut back brace with double

faced tape the brace’s bandsawn edge gets routed giving the surface shown.

Next Up – Assembling Seat/Back Braces & Seat Slat Preparation

No comments:

Post a Comment