This is the last post for this project. Between coats of lacquer on the shelf I can take care of

the few remaining bits of work on this project.

First is to assemble the drawer then reinstall the full extension metal

guides and do any minor adjustment so the drawer is centered in the opening.

With the drawer in place the false front can be added

which starts by locating and clamping the handle to the false drawer

front. Once that’s done pilot holes the

size of the screws root diameter get drilled through the front & into

handle. The blue tape on the drill bit

is my depth gauge.

Next using spacers, the false drawer front is centered in

the opening and clamped in place. With

that done using the already drilled pilot holes as guides the holes in the

actual drawer can be drilled. Here the

false drawer front is centered with spacers ready to be clamped and drilled.

Enlarging the holes in the false front so the screw

threads do not bite into it is next. I

want the screw threads to engage only with the handle so it pulls all the

pieces tight together. The holes in the

drawer also get enlarged. However, they

get drilled out larger still to provide room for adjustment to the position of

the drawer a little. In the photo below

the handle which is at the top has its pilot holes drilled, below that is the

false front with the pilot holes enlarged for clearance. On the bottom is the drawer itself whose

pilot holes were enlarged to allow for adjustment. Side note, on the extra holes in the

handle. They were for the screws that

temporarily attached blocks to the handle when it was being sprayed with

lacquer.

Once assembled the false front gets centered in the

opening and the attachment screws tightened.

Lastly, one additional shorter screw through the drawer into only the

drawer front gets added in the center.

I left the top with all its coats of lacquer for wet

sanding until the shelf was done too.

Both are wet sanded using the 8,000-grit pad. That takes care of any dust that might have

settled on the finish before it dried dust-free. The top photo shows the top’s wet sanding in

progress. On the far left just barely in

frame is the spray water bottle used to mist the surface. The sanding pad has the loop part on its back

while the circular block using has the hook half of the fastener on it. In the close-up you can see the misted water

droplets.

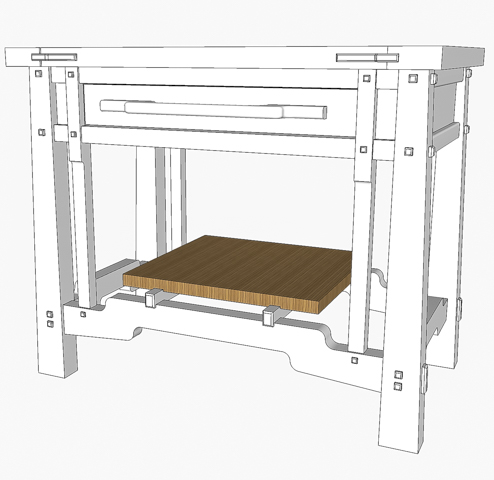

Once wet sanded the shelf gets installed first. As it had already been fitted with the

mounting holes drilled in the shelf and the screws run in all installing

required was setting in place and putting the screws back in. Here is what the installed shelf looks like

from the underside.

Adding the top is the last bit of work. That started by laying the top face down and

centering the base upside down on it.

Once centered the screw locations are marked in the top using a screw

large enough to fill the holes and slots width so the screw is centered. After that the base is taken off, pilot holes

drilled and the screws run in 5/8” because when permentaly installed that’s as

far as they go into the top. They are

removed, the base set back on the top and the screws reinstalled. It is a really tight squeeze getting the

screws in and tightened. The top drawing

below has the piece inverted with the top down.

The bottom drawing is from a different angle with the spindle and one of

the rails removed so the inside is visible.

As you can see it’s a pretty tight squeeze, there is only about 1 ½”

side to side room. Additionally, you

can’t get a straight shot with the screwdriver into the screws since the side

rail overhangs the side rail the screws run through.

The last bit of assembly is to put the drawer in which almost completes the project. It does need to set in the shop for a couple of weeks so the lacquer completely gasses off until there is no longer any odor from it. Below are a couple of views of the completed piece. Because this will be used as an end table in the living room next to my chair the top will get some abuse from things being piled up, drinks spilled and who knows what else. To provide protection a ¼” thick piece of plate glass will be added.