Next is to make risers that go between the dividers

and a cross brace that will go inside the lid.

The risers will lift the riffler’s cutting surface up and make them a

little easier to grab.

The grain in both these pieces are a little different

than what you would usually find in pieces like these. So as not to have a cross grain situation the

long edge will be end grain. The blanks

are cutoffs I saved when making the end piece blanks. I used a router with a 3/8” round over bit

to cut the top and bottom ending up with a bullnose edge. Here is the setup on the router table.

To cut the riser and brace off I used the table saw with

a slightly different setup. Rather than

measure between the fence and the blade for the kept piece I set the fence so the

cutoff was the kept piece. This is

because the kept piece is not very wide and has a rounded edge that I thought

might roll a bit as I made the cut. If

that happened the blade could grab it and that would be a bad thing. Making the cut as shown below gives a nice

wide flat surface to hold onto while making the cut.

With the riser blank cut I could start cutting the

individual pieces that go in the base.

Below is a photo that has the whole blank with the riser cut off, it set

in place in the base and a close-up.

With the piece length verified I clamped a playing card

to the fence as a stop making the cut just a little long. I used the card rather than a regular block

because I was worried that because the cut-off was the piece I kept with a regular stop it could get pinched between the stop and the

blade. If that happens things can get

really exciting in a hurry and not in a good way.

The pieces are cut just a fraction long because as

careful as I was when setting the divider spacing there are minor

differences. No more than a couple

hundredths of an inch but enough I wanted to be able to fit each one

exactly. Final fitting is done with a

12” disk sander and a miter gauge to keep the face square.

The only thing of note as I glued the risers in was the

use of a spacer to make sure when done they were all lined up straight. A single similar piece will be made for the

top that will act as reinforcement.

Next is to round over some of the edges. As a way of assuring that I routed just the

edges needed I marked the cut edges with chalk.

I will be holding the routed pieces in all different directions and it

would certainly be easy to get confused and route an edge that should not be

routed. Here is the lid marked and ready

to go. The roundover bit in the router

is a 1/8” radius.

Here is the lid on the base after routing. The corner circled in red is end grain and is

so small I was concerned that if I used the router to make the cut the odds of

a mishap were pretty good. It was pretty

easy to use sandpaper to match the radius and blend the two edges.

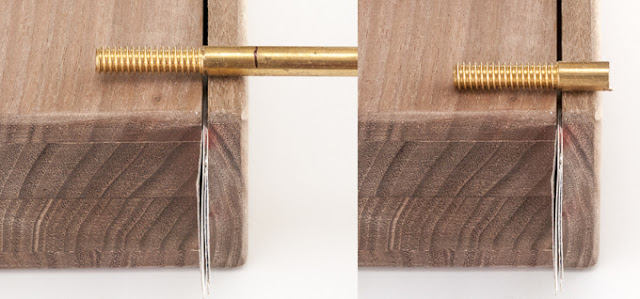

The pins that will hold the top in place and allow it to

open are next. I wanted to make the pins

out of ¼” diameter brass rod and had a heck of time finding it. I finally found a brass rod threaded on both

ends that was a replacement part for a water filler for a stock tank. As an added bonus the treaded ends will work

to help keep the pins in place. With the

top held in place with spacers I marked the pin length and cut it off with a

hacksaw.

Once cut I chucked the pin up in the lathe, used a fine

file to shape and bring it to the proper diameter as the rod was a bit

oversize. From there I used sandpaper

starting with 320 and ending with 1,500 wet then on to steel wool. Final work is with a cloth wheel loaded with

polishing rouge which gives me a fairly polished surface.

For feet I used the same process except using a file I

cut a decorative groove just above the bottom.

The little feet will be installed in a ¼” holes in the base. Below are all the brass pieces for the

project.

Next is the marking and drilling of the holes for the

brass pins. These need to be carefully

measured so the holes line up on each side.

To hold the top and bottom together while drilling I shimmed the gap

between the two pieces then taped everything in place. With that done I moved to the drill press,

clamped a tall extension board to the fence, checked for square, made sure the

drill was lined up with the center mark, clamped the piece in place and drilled

the hole. With one hole done I flipped

the piece keeping the same fact against the fence and drilled the other

side. Below you can see the total setup

plus a closer view. The depth of the

holes is critical as the pins need to bottom out in the holes so when they are

installed they only go in so far. With

this design there is no way to get them out if they get pushed in too far. The last bit of woodworking is drilling holes

for mounting the feet in. I used the

drill press using the process as above.

Finishing is next.

I am using Danish Oil rather than my usual lacquer finish because I

think that over time the case could get a little beat up. If that happens I can refurbish it by

applying another coat of oil. I started

with the top to get a feel for how the wood will react with the finish. Here is a photo of the top with one coat and

the bottom with none. This gives a good

idea of how the finish brings out the grain and richness of the walnut used.

Once the finishing was done I installed the feet. The piece of wood with the hole in it is my

stop. I put some epoxy in the hole, the

foot in the spacer and use a clamp to press the foot flush with the spacer. Follow the same process and presto all four

feet are set at the same level. At least

that was the plan. I must have bumped

one of the feet as I was cleaning the squeezed out epoxy off. I ended up with one being just a little to

deep. Once the epoxy has cured the fix

was pretty easy, I clamped a full sheet of sand paper down then rubbed the

piece back and forth until everything was level.

With the feet in, the last thing was to glue in the pins. I used yellow carpenters glue rather

than epoxy because this is a one shot install.

As I said once I push the pins in there is no way to get them out. I expected some squeeze out of glue when they

are installed and it did happen.

Cleaning up was a lot easier with the water soluble yellow glue than it

would have been with epoxy.

After letting the glue cure overnight I put the rifflers in the box and was done.

No comments:

Post a Comment