Because I could apply the wipe-on poly finish to all

sides of the central column at once I was done with it before I completed all

the different faces of the boxes and baffles.

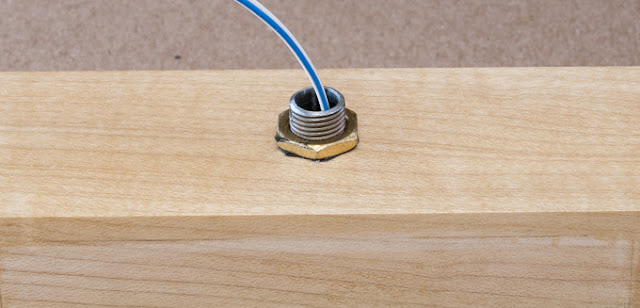

With the column finish completed I could epoxy in the threaded pipe that

the light fixtures will get attached to.

After letting the epoxy cure overnight, I took the light

brackets off to make pulling the wire easier.

I started by tying a 3/8” X #4 screw to a pull cord and stuffing it down

through the epoxied pipe. To pull the

cord I attached a magnet to the end of a dowel then fed that up the chase in

the column until the magnet grabbed the screw.

Gently pulling the dowel out gave me my pull cord. The photo below shows the magnet taped to the

dowel, the screw and the pull cord running into the column.

Here the pull cord is taped to the electrical wire that

will power the lights. If the wire looks

small that’s because it is. Since I will

be using a 6.5-watt LED bulb which only draws .05 Amps a smaller wire works

just fine. In addition, I can get a

light output that matches an old 60-watt incandescent bulb without the

heat.

I digress, sorry back to pulling the wire. With a gentle pull on the cord while pushing

the wire I had no problem getting the wires pulled through the chase and out

the bottom of the column.

With the wire in place it’s a simple matter to put the

fixture brackets back on or at least I thought it was going to be. The first bracket I put on did not line up

the way it should have. What I found out

was that the threads starting points in the brackets vary so in order to get

them lined up square I had to find the one that was used to set the threaded

pipe. Not hard it just took a bit of

time before I realized what was going on and then more time playing musical chairs

with the brackets. Once the brackets

were matched up with their mating pipes it was a simple matter to make the

electrical connections to the fixtures and screw them to the brackets.

With the wire in place it’s a simple matter to put the

fixture brackets back on or at least I thought it was going to be. The first bracket I put on did not line up

the way it should have. What I found out

was that the threads starting points in the brackets vary so in order to get

them lined up square I had to find the one that was used to set the threaded

pipe. Not hard it just took a bit of

time before I realized what was going on and then more time playing musical chairs

with the brackets. Once the brackets

were matched up with their mating pipes it was a simple matter to make the

electrical connections to the fixtures and screw them to the brackets.

The finishing touch to the fixtures is a decorative cover

that I had to cut to length. The covers

are fairly flexible plastic which makes getting a nice square smooth cut a

problem. As far as I could tell just

about everything I have has some sort of problem making the cut. The solution ended up fairly easy although a

little odd. I turned a piece of cedar on

the lath to slightly tapered cylinder matching the interior diameter of the

plastic cover. The cover is slid cover

over tapered cylinder until it fits snugly and a skew chisel is used to make

the cut. This gives me a smooth square

cut which fit the fixture perfectly.

Next is to glue and screw the spacers to the boxes. To make sure everything went together well I

test fitted each spacer/box connection.

Getting the screws in was harder than I thought. Since there is such a narrow space between

the sides of the box I had to use a right-angle attachment on the drill with a

very short driver to even get in there.

In fact, to make the last half a turn on the screw I ended up using a ¼”

drive socket with the driver in it. The photo below shows what I mean.

In the last post, I talked about a slight relief cut on

the underside of the spacer because of the little mound created when a screw

enters a piece of wood which can keep the piece from screwing down tight. In the photo below you can see an example of what I mean.

Once the test fit of the spacer to the box was done I

disassembled it, added some glue and screwed the two pieces together. Nice thing about using the screws is that no

clamps are needed to hold the pieces in place while the glue cures. At last all the pieces that go into the box

assembly are done and put together. The

last step is to glue them to the column.

This is what the assembly looks like glued and clamped in place.

There is a bit of setup that goes into locating the box

assembly. You may have noticed the

spacer is not flush with the face of the column but sits back about 1/16” from

the edge. You can see this in the

left-hand drawing below. So that I could

get a nice consistent setback of the spacer from the face of the column I made

a little jig by carefully milling a couple of pieces the same thickness as the

setback and gluing them to a plywood base.

You can see the jig cradling the column with the spacer setting on it. The piece of green tape on the column acts as

my locating mark for the top of the spacer.

One down and two to go.

There is a bit of setup that goes into locating the box

assembly. You may have noticed the

spacer is not flush with the face of the column but sits back about 1/16” from

the edge. You can see this in the

left-hand drawing below. So that I could

get a nice consistent setback of the spacer from the face of the column I made

a little jig by carefully milling a couple of pieces the same thickness as the

setback and gluing them to a plywood base.

You can see the jig cradling the column with the spacer setting on it. The piece of green tape on the column acts as

my locating mark for the top of the spacer.

One down and two to go.

Once all the boxes are glued to the column I added the

baffles. They slide into a slot that

runs around three sides of the column and are glued in place. It’s a pretty snug fit and no clamps are

required. After the glue cures holding

the baffles in place I glued and screwed the column to the base completing all

the wood working for the piece. That

left just the wiring to finish. Below is

a photo once I had soldered the wires together, encased them in heat shrink

tubing and added a clamp to act as strain relief.

Here is the finished lamp and the prototype setting on

the workbench along with the design drawing.

Pretty similar except for the base, which although revised in the

drawing and final product was not rebuilt from the first prototype version.

This is the last pair of photos for this project. The one on the left is the lamp alone and the

one on the right is the lamp at my desk with the lights on. I am happy with the final product in it does

just what I wanted. It provides good

light on the desk without any visible bulbs, glare off the computer screen and

does not put out a lot of heat.

I do have to say that there is a lot more to this than

first meets the eye. It’s simple looking

but sure was not simple to build. That's due to having all the joints exposed with no trim or anything similar. Any error however slight would really show up.